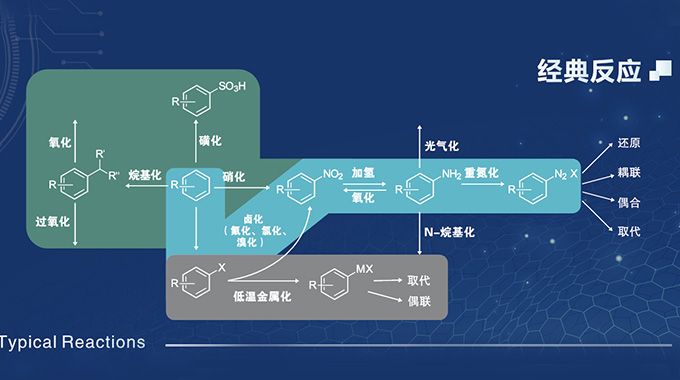

Related Fields

Monomer photoresist&OLED raw materials

PCB、 Display panel LED、 Research and development, production, and CDMO of various high, medium, and low-end photoresist monomers and OLED raw materials for semiconductors (g/i line, KrF, ArF, EUV).

Photoinitiator&photoacid

Including various types of photosensitive material raw materials such as traditional photoinitiators, PAG, PAC, etc.

Other related supporting materials

Chemical raw materials for other additives, auxiliaries, cleaning agents, etc.

Company Profile

Focusing on high-end semiconductor electronic chemicals - research and development, production, and intelligent manufacturing for the future

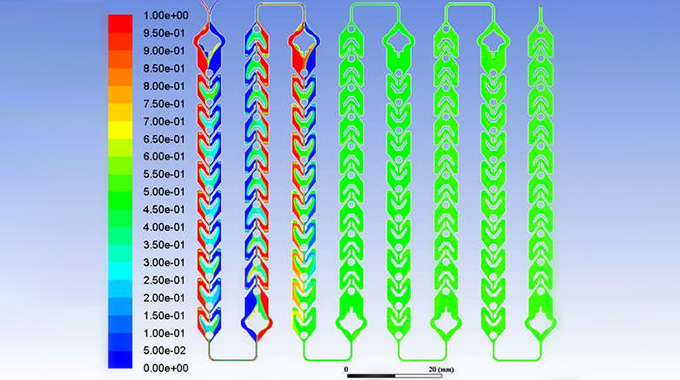

Ningbo Weigexin Material Technology Co., Ltd. focuses on the research and development, production, and sales of high-end electronic chemicals in semiconductors. The company takes microchannel continuous flow technology as its core, breaks through the technical barriers of high difficulty electronic chemicals, and establishes three major research and development and production bases in Ningbo, Kaifeng, and Gansu, providing safe, efficient, and customized chemical solutions for the global semiconductor industry chain.

20+Year by year

Experience in Chemical Synthesis

20PPbbelow

PPb level purification capability

30000+

Molecular Block Warehouse

Core advantages